- 20~30 % Work efficiency increases linearly

- 30-50 % Artificial Reduction

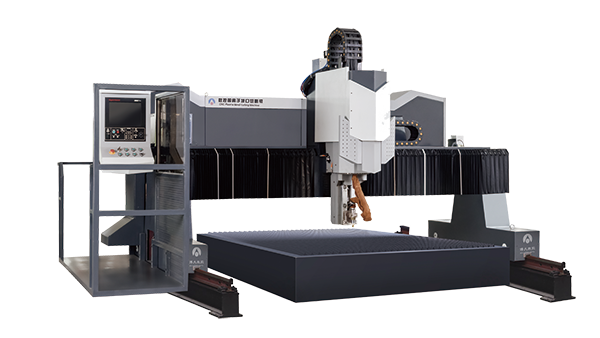

Beam imported linear guide, "L-shaped over-positioning" technology installation, extremely high precision, 400mm ultra-wide mobile body. The rotating head adopts high-precision combined turntable bearing, rotation-yaw motion mode, double linkage, and harmonic reducer. The product has won a number of national patents.

The structure is atmospheric, solid and durable. The structural parts are tempered to remove internal stress, and are processed by imported high-precision gantry pentahedron machining centers, which have high strength, rigidity and precision. Torch Collision Protection: Magnetic anti-collision, not afraid of hitting the gun!

The frame is designed with heavy-duty reinforced structure, with good strength and high running speed. Saving materials, saving labor, improving efficiency, intelligent, one-click cutting.

A strong R&D team ensures the quality and technology of the equipment;

Sophisticated equipment and complete technology ensure the accuracy of the equipment;

Strict on-site management and testing ensure its excellent workmanship;

The perfect after-sales service team ensures the stable operation of the equipment;

| Standard Specifications of Machine Tool | Control device | Cutting device | Appendix | Precision quality | |||||

| Processing steel plate size range | According to customer needs | Control System | Treasure | Plasma | Fine cutting plasma (import) | Soot purification device | Cutting form detection standard | Fine cut | |

| Base rail (longitudinal) | Grinding rails | LH fine cutting plasma (domestic) | Lubrication device | ||||||

| Gantry rail (horizontal) | Linear Guides | Drive Servo Motor | Panasonic Servo | Laser pointing device | |||||

| Machine tool gantry structure | Moving beam gantry | A6 bus | Torch angle control device | Fine cutting plasma (import) | Warning Light | The whole machine operation test standard | Factory standard | ||

| Slewing mechanism | Bevel cutting | Cutting torch configuration | Independent arc voltage height adjustment | LH fine cutting plasma (domestic) | Industrial air conditioner | Other | |||

| Cutting torch configuration | Plasma | System-integrated arc voltage height adjustment | |||||||

Malaysia's large-scale construction machinery industry customer site

Large pressure vessel industry customer site

Steel structure manufacturing industry customer site

Construction and bridge industry customer site

Plastic machinery industry customer site

South African construction machinery industry customer site

Site of customer abroad

Site of customer abroad

Site of customer abroad

Site of customer abroad

Site of customer abroad

Site of customer abroad

Site of customer abroad

Site of customer abroad

Site of customer abroad

Site of customer abroad

Site of customer abroad

Site of customer abroad

Site of customer abroad

Site of customer abroad

Site of customer abroad

Site of customer abroad

Site of customer abroad

Site of customer abroad

Site of customer abroad

Site of customer abroad