Pipe Profile Cutting Machine

-

Discover the product

Discover the productAutomatic Loading and Unloading Pipe Cutting Machine (With Material Warehouse)

The automatic loading and unloading pipe cutting machine (with material warehouse) can be developed and researched for batch manufacturing in specific industries,and can achieve layered and classified storage of pipes (muti-layer material warehouse),auto-matic feed conveying (pipe loading and unloading),and chuck clamping cutting;The use of medium to hgh power lasers for cutting and processing pipes below 8mm can achieve centralized completion of pipe ctting,dilling,and other processing steps at one time.

-

Discover the product

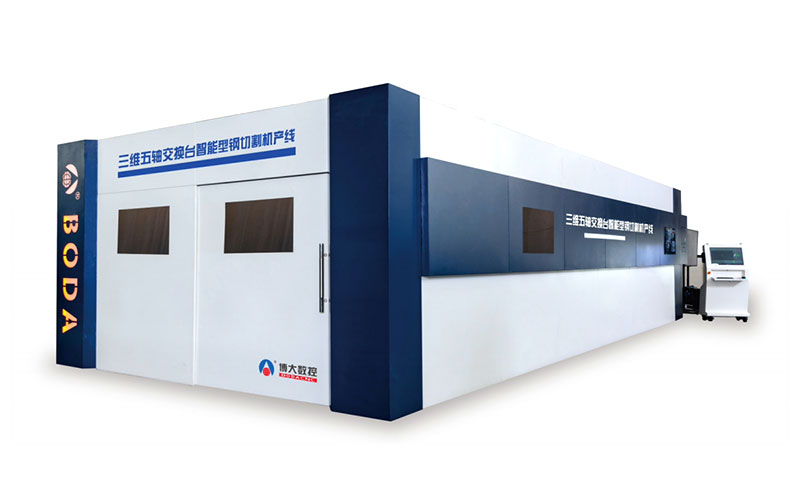

Discover the productCNC Pipe Profile Cutting Machine

BDZG series CNC pipe profile cutting machine is a high performance,high standard,multi-purpose pipe profile cutting machine,can achieve round pipe,square pipe,rectangular pipe,oval pipe and Angle steel,channel steel,H-shaped steel and other special-shaped pipe cutting,optional floating support,automatic loading and unloading and other functions.According to the needs,the configuration from 2 chuck to 4 chuck,to meet the cutting accuracy requirements of different types of pipes.When the cutting head cuts offside,it can realize the zero tail cutting of all pipes.

-

Discover the product

Discover the product560 Three-Chuck Pipe Profile Cutting Machine

The CNC 560 Three-Chuck Pipe Profile Cutting Machine can efficiently and precisely complete the laser cutting processing of various pipe profilesIt can perform three-chuck adaptive logic loading and unloading CNC cutting for medium 560mm pipe pro- files.The high-power laser it is equipped with can meet the bevel cutting requirements of thick-walled pipes.It adopts a mature and reliable high-power laser pipe cutting system and the correspond- ing pipe profile nesting software.It can recognize 3D models and automatically complete the conversion of processing programs.