CNC plasma cutting machine: efficient and precise metal cutting tool

CNC plasma cutting machines, a product of modern technology and mechanical engineering, are thriving in the metal cutting field with their unique advantages. Using high-energy plasma to cut metal materials, they are an indispensable tool in numerous industries for their efficiency, precision, and automation.

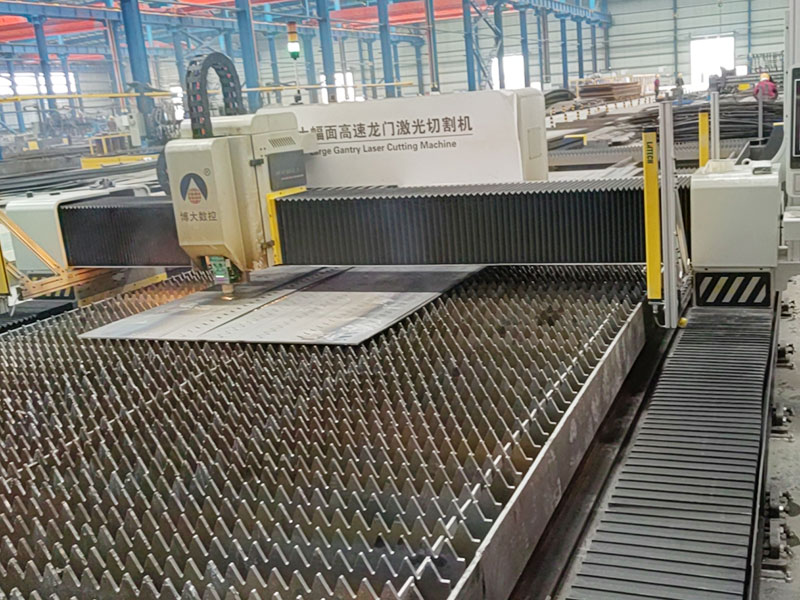

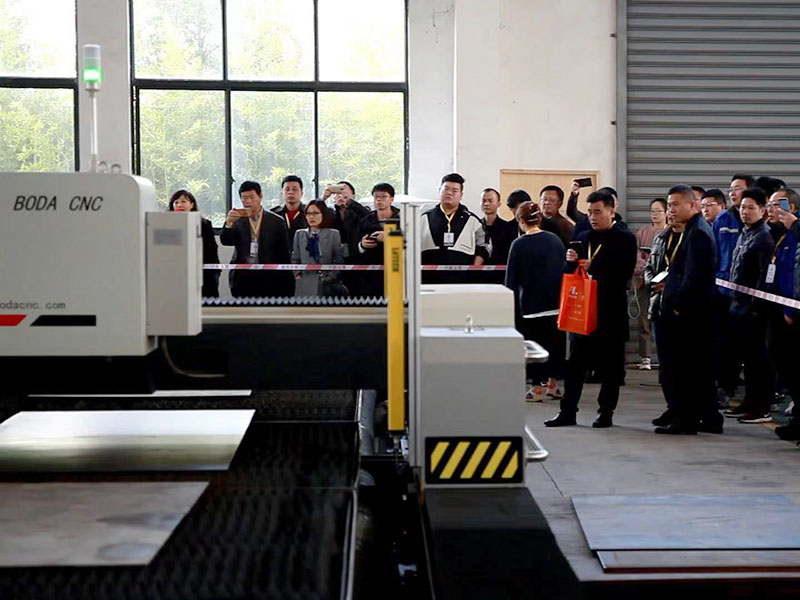

CNC plasma cutting machines are primarily divided into three types: portable, cantilever, and gantry. Portable models are compact and lightweight, suitable for cutting small areas. Cantilever models are moderately priced and take up less space, but are less stable. Gantry models offer a stable structure, high cutting precision, and can meet a variety of configuration requirements, but are relatively expensive. Each type of cutting machine has its own advantages, and users can choose one based on their specific needs.

Their advantages lie in their fast cutting speed, high precision, excellent quality, simple operation, and low cost. Compared to traditional cutting methods, CNC plasma cutting machines not only significantly improve production efficiency but also ensure consistent cutting quality. Their automated control system simplifies operation, reduces labor costs, and improves cutting costs.

When using a CNC plasma cutting machine, first check the plasma power supply's air inlet pressure and the startup alarm. Then, activate the dust collector. After the CNC system is fully started, perform preparatory steps such as returning all axes to zero and replacing consumable parts. Next, load the cutting program and database, calibrate and save the program's cutting starting point, adjust the gas settings, and start cutting. During the cutting process, it's important to closely monitor the cutting signals. If any problems arise, stop cutting and troubleshoot immediately.

CNC plasma cutting machines are widely used in a variety of fields, including shipbuilding, automotive, metallurgy, and machinery manufacturing. In shipbuilding, they enable rapid and precise cutting of materials such as cold-rolled and hot-rolled steel sheets; in automotive manufacturing, they efficiently cut components such as body panels and windshields. Furthermore, they play an irreplaceable role in metallurgy and machinery manufacturing.

In short, CNC plasma cutting machines, with their efficient and precise cutting capabilities, have become indispensable processing equipment in modern industry. In the future, with continued technological advancements and expanding application areas, they will continue to play an even greater role in metal cutting, contributing to industrial development.