From manual to intelligent: a quantum leap in tube steel cutting technology

In the metalworking industry, tubular steel cutting is a fundamental and crucial process. From simple manual operation to today's highly intelligent cutting equipment, each technological innovation has profoundly impacted production efficiency and cost control. This article will review this journey and explore the remarkable advancements in tubular steel cutting technology, from manual to intelligent.

In the past, cutting steel tubulars was primarily a manual process. Workers wielded handheld cutting tools, such as abrasive cutters, relying on their experience and skill. While flexible, this method was inefficient and required extremely high technical skills. Furthermore, manual operation struggled to maintain cutting accuracy, often leading to material waste and increased processing costs.

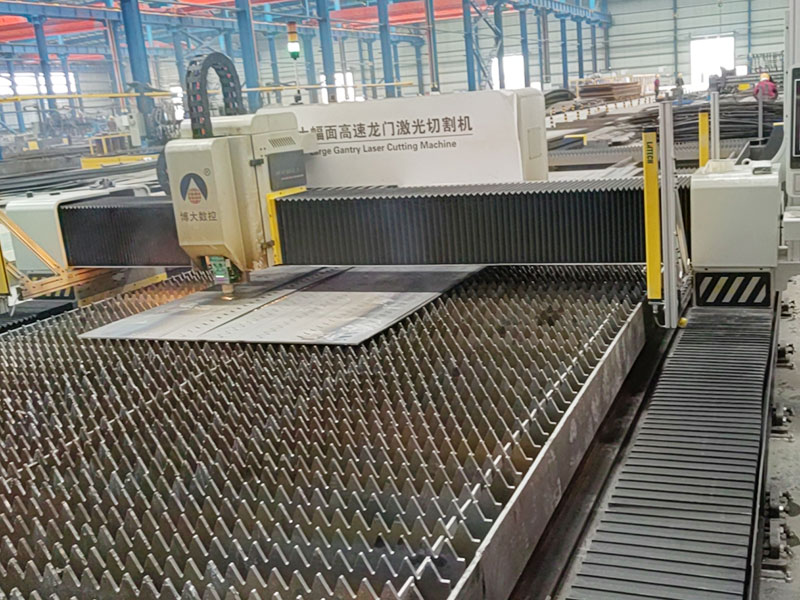

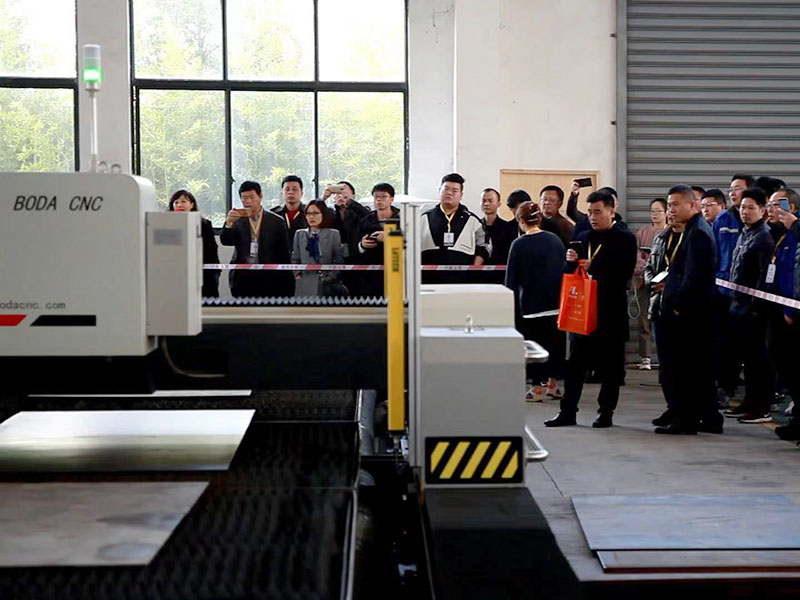

With the advancement of technology, intelligent cutting technology has emerged. Intelligent tubular steel cutting devices utilize advanced sensors, control systems, and cutting processes to achieve precise cutting of tubular steel. These devices not only offer high cutting speeds but also exceptional precision, improving production efficiency and product quality. More importantly, intelligent cutting devices can automatically adjust cutting parameters according to pre-set programs, reducing manual intervention, operational complexity, and costs.

Compared to traditional manual cutting, intelligent cutting technology offers significant advantages. In terms of efficiency, intelligent cutting devices enable continuous and stable cutting operations, boosting production efficiency. In terms of cost, their high cutting precision reduces material waste, while the reduced manual intervention also reduces labor costs. Furthermore, intelligent cutting devices offer advantages such as enhanced safety and ease of maintenance, further enhancing their competitiveness in the metalworking industry. Today, more and more metalworking companies are adopting intelligent cutting technology to cope with increasingly fierce market competition. The widespread adoption of this technology has not only driven the transformation and upgrading of the metalworking industry but also injected new vitality into sustainable socioeconomic development.

Looking back, we are deeply moved by every technological advancement; looking forward to the future, we look forward to the application and expansion of intelligent cutting technology in even more fields. The leap forward in tubular steel cutting technology, from manual to intelligent, is a vivid example of how technology is changing our lives. We have reason to believe that in the near future, intelligent cutting technology will lead the metalworking industry towards an even brighter future.