Intelligent Robot Steel Cutting Production Line: Injecting Strong Power into the Manufacturing Industry

Every technological innovation in the manufacturing industry is like a powerful force, propelling the industry forward. The emergence of intelligent robotic steel cutting production lines has injected new vitality and possibilities into this field, improving production efficiency while also providing strong support for accuracy, safety, and sustainability.

The intelligent robotic steel section cutting production line is a modern production solution that integrates advanced robotics, automated control systems, high-precision sensors, and intelligent algorithms. The key to this production model is its "intelligence," meaning the line can autonomously complete the entire process, from material identification and cutting path planning to precise execution, based on pre-set programs or real-time data, with minimal or no human intervention.

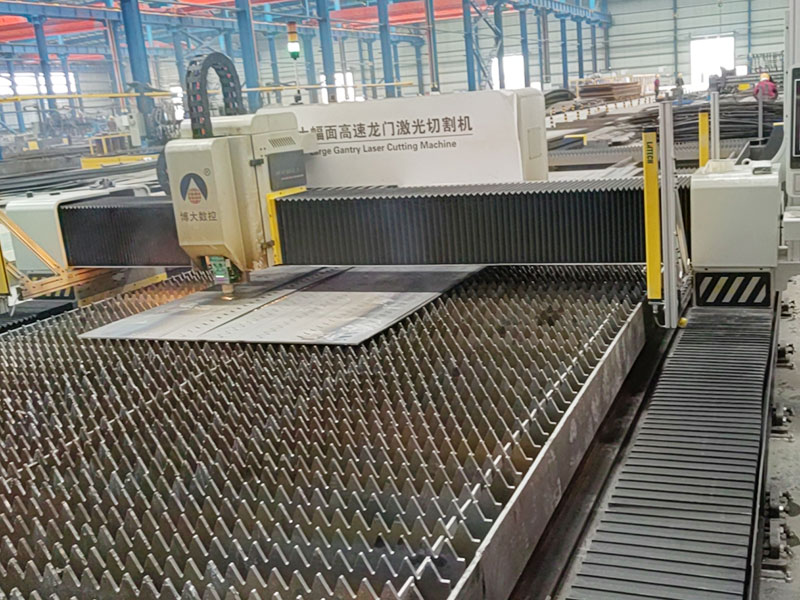

Traditional steel section cutting requires manual operation of cutting equipment, which is labor-intensive and inefficient, especially when dealing with complex shapes or large-scale production. The intelligent robotic steel section cutting production line revolutionizes this situation. Using high-speed mechanical tubes and precise cutting heads, the robots can complete cutting tasks at astonishing speed while maintaining exceptional precision. This not only significantly shortens production cycles but also significantly improves product quality and consistency, giving companies a competitive edge in the market.

Safety is a crucial issue in the manufacturing industry. During the steel cutting process, factors such as flying sparks, hot cutting surfaces, and mechanical movement can all pose safety hazards. The intelligent robotic steel cutting production line, with its fully enclosed design, multiple safety measures, and intelligent monitoring system, effectively reduces the likelihood of accidents and provides a safer working environment for operators. Furthermore, leveraging high-precision sensors and advanced visual recognition technology, the robot can accurately position and cut steel sections, even with complex shapes, ensuring flawless products.

While pursuing efficient production, the intelligent robotic steel cutting production line also actively responds to the call for sustainable development. By optimizing cutting paths, reducing material waste, and improving energy efficiency, robotic cutting is more environmentally friendly and energy-efficient than traditional methods. Furthermore, the intelligent production management system enables real-time monitoring of energy consumption and emissions during the production process, providing data support for companies to formulate energy-saving and emission-reduction strategies and help them achieve green production goals.

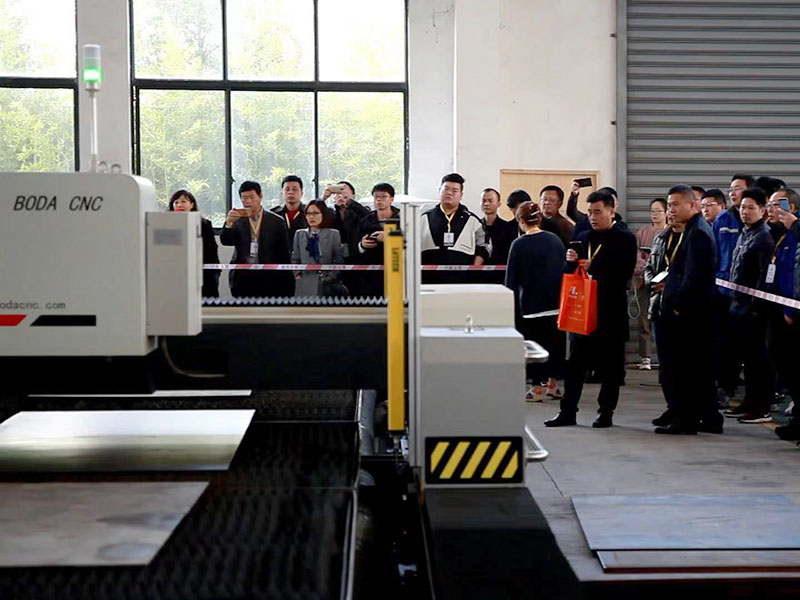

The application of the intelligent robotic steel cutting production line not only disrupts traditional production models but also represents a significant force in driving the transformation and upgrading of the manufacturing industry towards intelligent and automated production. It has promoted collaborative innovation across the entire supply chain and driven the rapid development of related industries, such as robotics, sensor technology, and artificial intelligence algorithms. At the same time, the advancement of this technology also requires companies to continuously improve their employees' skills and cultivate interdisciplinary talents adapted to the era of intelligent manufacturing, laying a solid foundation for their long-term development.

Jiangsu Boda CNC Complete Equipment Co., Ltd. has been dedicated to the R&D, customization, and production of CNC hot-cutting equipment and related products for 22 years. This integrated enterprise combines production, learning, and research. We are one of the few companies in China capable of producing a complete range of over 20 products across five product lines, including CNC plasma cutting machines for sheet metal, plasma cutting machines for pipes and profiles, laser cutting machines, custom-made cutting machines, and dust purifiers for cutting. If you have any questions, please feel free to contact us!