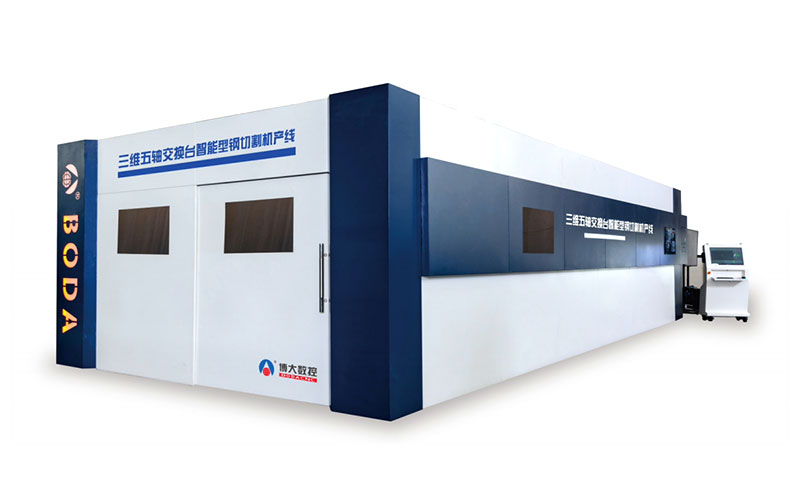

Intelligent CNC metal circular saw machine reshapes metal cutting to a new level

- Whatsapp:+86 18861115817

- E-mail:boda@bodacnc.com

Detail

In the metalworking industry, every innovation in cutting technology propels the industry to new heights. With the rapid development of intelligent manufacturing technology, intelligent CNC metal circular saws, leveraging their core advantages of digitalization and intelligence, have broken through the limitations of traditional cutting methods, redefining the precision, efficiency, and flexibility of metal cutting and opening up a new path for development in the metalworking industry.

The intelligent CNC system is the "brain" behind this quantum leap in the performance of metal circular saws. Unlike traditional circular saws, which rely on manual experience to adjust parameters, intelligent CNC metal circular saws are equipped with advanced CNC operating systems and industrial-grade computers. Operators simply enter parameters such as the material type, specifications, cutting dimensions, and angles on the touchscreen, and the system instantly generates the optimal cutting plan. For example, for steel and aluminum alloys with varying hardnesses, the system automatically adjusts the saw blade speed, feed rate, and cutting pressure based on a pre-set material database. Furthermore, through the precise drive of servo motors, coupled with high-precision ball screws and linear guides, the equipment maintains a cutting error within ±0.05 mm, achieving micron-level cutting accuracy. This intelligent operation not only reduces reliance on operator expertise but also ensures exceptional precision with every cut.

Efficient operation is a key factor in the reshaping of cutting performance achieved with intelligent CNC metal circular saws. Traditional cutting equipment often requires time-consuming manual adjustments when switching between different material specifications or adjusting cutting parameters, resulting in low production efficiency. However, intelligent CNC metal circular saws, with their automated rapid die change and parameter switching capabilities, can be ready for production in minutes. Their high-speed rotating saw blades, combined with an intelligent feed system, automatically adjust cutting speed based on material thickness, ensuring continuous and efficient operation. For example, at a large steel structure fabrication plant, the introduction of intelligent CNC metal circular saws enabled a batch of steel beams to be cut in 20 minutes, a task that previously required four operators to complete in an hour. This now requires only one operator to complete the task, achieving high-quality results. This represents a threefold increase in production efficiency and significantly shortened project delivery cycles.

In the metalworking industry, every innovation in cutting technology propels the industry to new heights. With the rapid development of intelligent manufacturing technology, intelligent CNC metal circular saws, leveraging their core advantages of digitalization and intelligence, have broken through the limitations of traditional cutting methods, redefining the precision, efficiency, and flexibility of metal cutting and opening up a new path for development in the metalworking industry.

The intelligent CNC system is the "brain" behind this quantum leap in the performance of metal circular saws. Unlike traditional circular saws, which rely on manual experience to adjust parameters, intelligent CNC metal circular saws are equipped with advanced CNC operating systems and industrial-grade computers. Operators simply enter parameters such as the material type, specifications, cutting dimensions, and angles on the touchscreen, and the system instantly generates the optimal cutting plan. For example, for steel and aluminum alloys with varying hardnesses, the system automatically adjusts the saw blade speed, feed rate, and cutting pressure based on a pre-set material database. Furthermore, through the precise drive of servo motors, coupled with high-precision ball screws and linear guides, the equipment maintains a cutting error within ±0.05 mm, achieving micron-level cutting accuracy. This intelligent operation not only reduces reliance on operator expertise but also ensures exceptional precision with every cut.

Efficient operation is a key factor in the reshaping of cutting performance achieved with intelligent CNC metal circular saws. Traditional cutting equipment often requires time-consuming manual adjustments when switching between different material specifications or adjusting cutting parameters, resulting in low production efficiency. However, intelligent CNC metal circular saws, with their automated rapid die change and parameter switching capabilities, can be ready for production in minutes. Their high-speed rotating saw blades, combined with an intelligent feed system, automatically adjust cutting speed based on material thickness, ensuring continuous and efficient operation. For example, at a large steel structure fabrication plant, the introduction of intelligent CNC metal circular saws enabled a batch of steel beams to be cut in 20 minutes, a task that previously required four operators to complete in an hour. This now requires only one operator to complete the task, achieving high-quality results. This represents a threefold increase in production efficiency and significantly shortened project delivery cycles.