Products

-

Discover the product

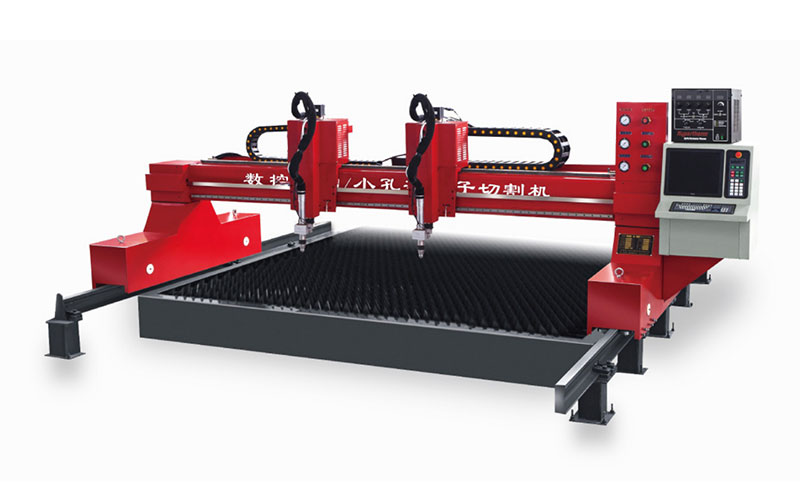

Discover the productCNC High-Speed Rail Type Gantry Laser Cutting Machine

BDLC series laser cutting machine is alarge format CNC gantry style high speed laser cutting machine.Super large processing table is suitable for the big plate cutting with dfferent length and width.It is mainly used in many industries such as steel structure, machinery,shipyard,locomotive,pressure vessel,etc.and mainly used for the cutting of plate with 6mm-35mm.

-

Discover the product

Discover the productCNC Gantry Laser Bevel Cutting Machine

BDLC series laser cutting machine is a large format CNC gantry style high speed laser cutting machine.Super large processing table is suitable for the big plate cuting with ifferent length and width.It is mainly used in many industries such as steel structure, machinery,shipyard,locomotive,pressure vessel,etc.and mainly used for the cutting of plate with 6mm-35mm.

-

Discover the product

Discover the productExchange Table CNC Laser Cutting Machine

CNC exchange table laser cutting machine integrates advanced laser technology and high-precision CNC system,designed for efficient cutting of sheet metal.The equipment adopts the design of double table,which realizes the uninterrupted processing flow and greatly improves the production efficiency.Its intelligent control system makes operation easy whle reducing manual intervention and improving production safety.

-

Discover the product

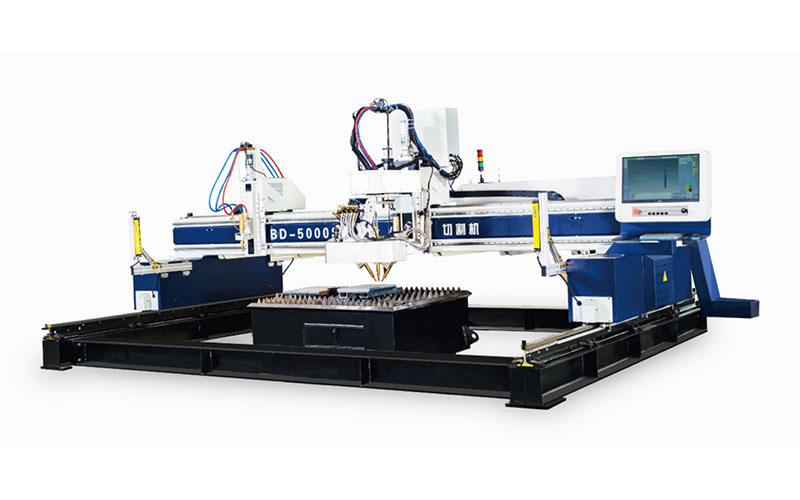

Discover the productCNC High-Precision Double-Head Plasma Cutting Machine

BDPC Series New Generation of CNC High-Precision Plasma Cut- ting Machine not only has superior performance,but also adopts an industrialized design,which enables the perfect fusion of tech- nology and art and creates the ultimate version of the flat-plate cutting machine.

-

Discover the product

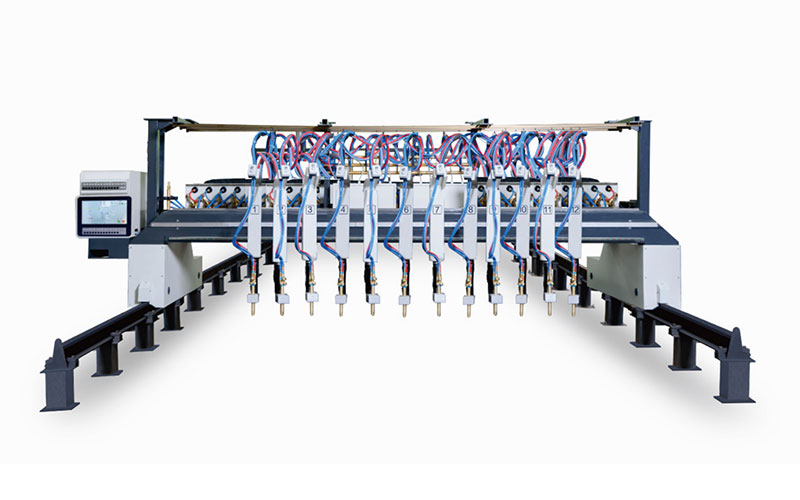

Discover the productHigh Performance CNC Plasma Bevel Cutting Machine

The CNC plasma AB bevel cutting machine can achieve automatic control of the entire process of direct cutting and bevel cutting of carbon steel/stainless steel plates,with fast cutting speed,high cutting accuracyand good cutting quality.As the fifth generation model of BODA,inheriting 15years of bevel cutting experience,the design,manufacturing,installation,and debugging of the entire machine are completely completed under the ISO9001 quality monitoring program.

It can be equipped with an automatic marking device,and the bevel cutting accuracy reaches±0.5mm. -

Discover the product

Discover the productAutomatic Loading and Unloading Pipe Cutting Machine (With Material Warehouse)

The automatic loading and unloading pipe cutting machine (with material warehouse) can be developed and researched for batch manufacturing in specific industries,and can achieve layered and classified storage of pipes (muti-layer material warehouse),auto-matic feed conveying (pipe loading and unloading),and chuck clamping cutting;The use of medium to hgh power lasers for cutting and processing pipes below 8mm can achieve centralized completion of pipe ctting,dilling,and other processing steps at one time.

-

Discover the product

Discover the productCNC Pipe Profile Cutting Machine

BDZG series CNC pipe profile cutting machine is a high performance,high standard,multi-purpose pipe profile cutting machine,can achieve round pipe,square pipe,rectangular pipe,oval pipe and Angle steel,channel steel,H-shaped steel and other special-shaped pipe cutting,optional floating support,automatic loading and unloading and other functions.According to the needs,the configuration from 2 chuck to 4 chuck,to meet the cutting accuracy requirements of different types of pipes.When the cutting head cuts offside,it can realize the zero tail cutting of all pipes.

-

Discover the product

Discover the product560 Three-Chuck Pipe Profile Cutting Machine

The CNC 560 Three-Chuck Pipe Profile Cutting Machine can efficiently and precisely complete the laser cutting processing of various pipe profilesIt can perform three-chuck adaptive logic loading and unloading CNC cutting for medium 560mm pipe pro- files.The high-power laser it is equipped with can meet the bevel cutting requirements of thick-walled pipes.It adopts a mature and reliable high-power laser pipe cutting system and the correspond- ing pipe profile nesting software.It can recognize 3D models and automatically complete the conversion of processing programs.